“As we all know, a production line is only as strong as its weakest link. It is crucial that all component parts are optimized for their purpose and adequately maintained to outperform throughout their life cycle. This also goes for grippers, which have a greater impact on productivity and profitability than many would believe, says Lennart Johansson, Product Manager Line at AP&T.

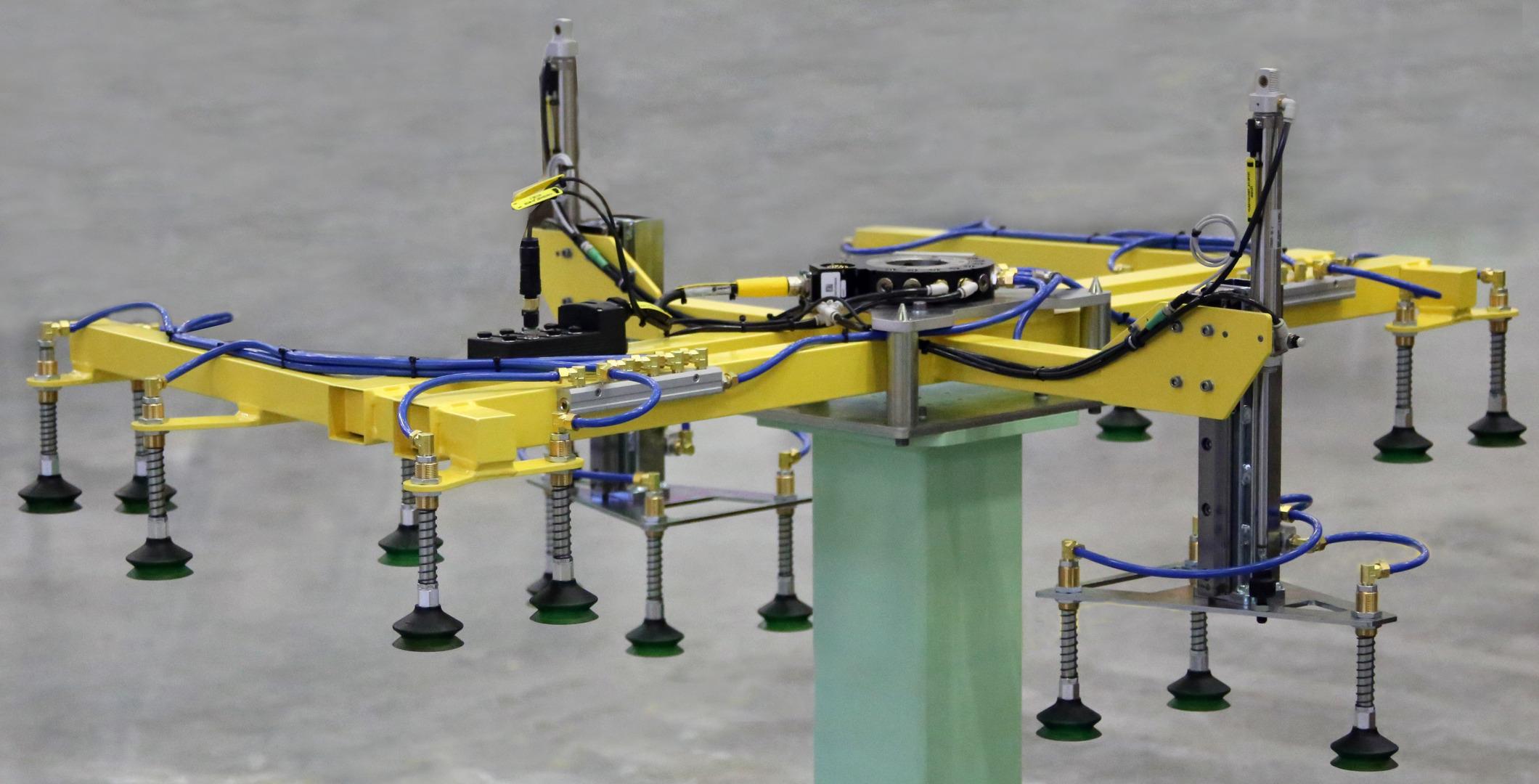

All AP&T lines are delivered with original grippers, but as production changes it is common to add or exchange the original grippers with new ones. For grippers to function as they were intended, it is vital that construction and installation are done right. An incorrect or unnecessarily complicated connection can have a negative effect on cycle and set-up times.

“If the dimensions of the pneumatic connections are wrong, it may take longer to obtain a vacuum in the gripper, making the process longer than it need be. And to minimize set-up times, it is important that the gripper design enables quick and safe exchanges. Just one or two seconds added to the cycle time can result in several weeks of lost production in a year,” says Henrik Vesterlund, Product Manager of AP&T Aftermarket Services.

Customers in need of new grippers or who just want to look over the existing ones in their production line are welcome to contact AP&T for new products, original parts or service.