Japanese Unipres supplies many of the world’s major car manufacturers with car body parts made out of pressed sheet metal. The global group has now decided to invest in two complete press hardening lines from AP&T. The first of the two lines will begin operating at Unipres’s British manufacturing center in Sunderland at the beginning of 2020. The second line will be delivered to the group’s French plant in Biache Saint Vaast in March 2020.

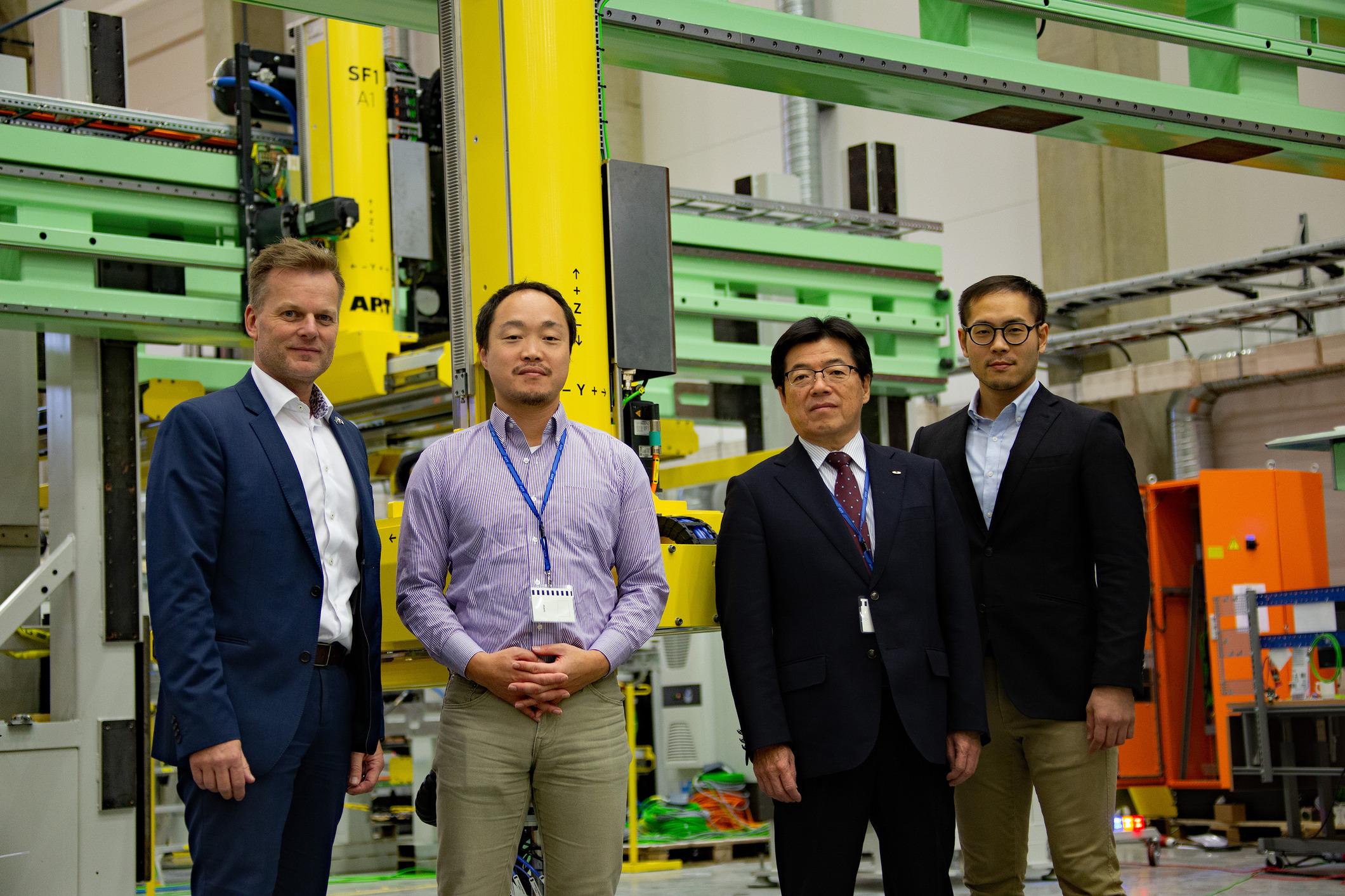

“AP&T’s reliable technology, extensive experience of press hardening and ability to provide quick service are some of the most important reasons underlying our decision to collaborate with AP&T,” says Senior Vice President Ryoji Maeda, Advanced Engineering Development Center, UNIPRES R&D CO., LTD.

“We are naturally delighted to be entrusted with producing complete solutions that meet Unipres’s high demands for short cycle times and extensive automation. Both of the lines have advanced technology. For example, all of the tooling and gripper changes are fully automated. The lines are also equipped with sophisticated press monitoring, which ensures a consistently high level of quality for the manufactured parts,” says AP&T Technical Sales Manager Peter Robisch.

AP&T’s business model — One Responsible Partner® — which entails AP&T taking full responsibility for all of the production equipment and having all of the required expertise in-house also played an important role in the procurement. Another important aspect was AP&T’s global operations, which allow the company to offer service and spare parts supply where customers operate.

To date, AP&T has delivered and installed over 120 press hardening lines all over the world.