Forming of High-Strength Aluminum

Lower weight and higher strength

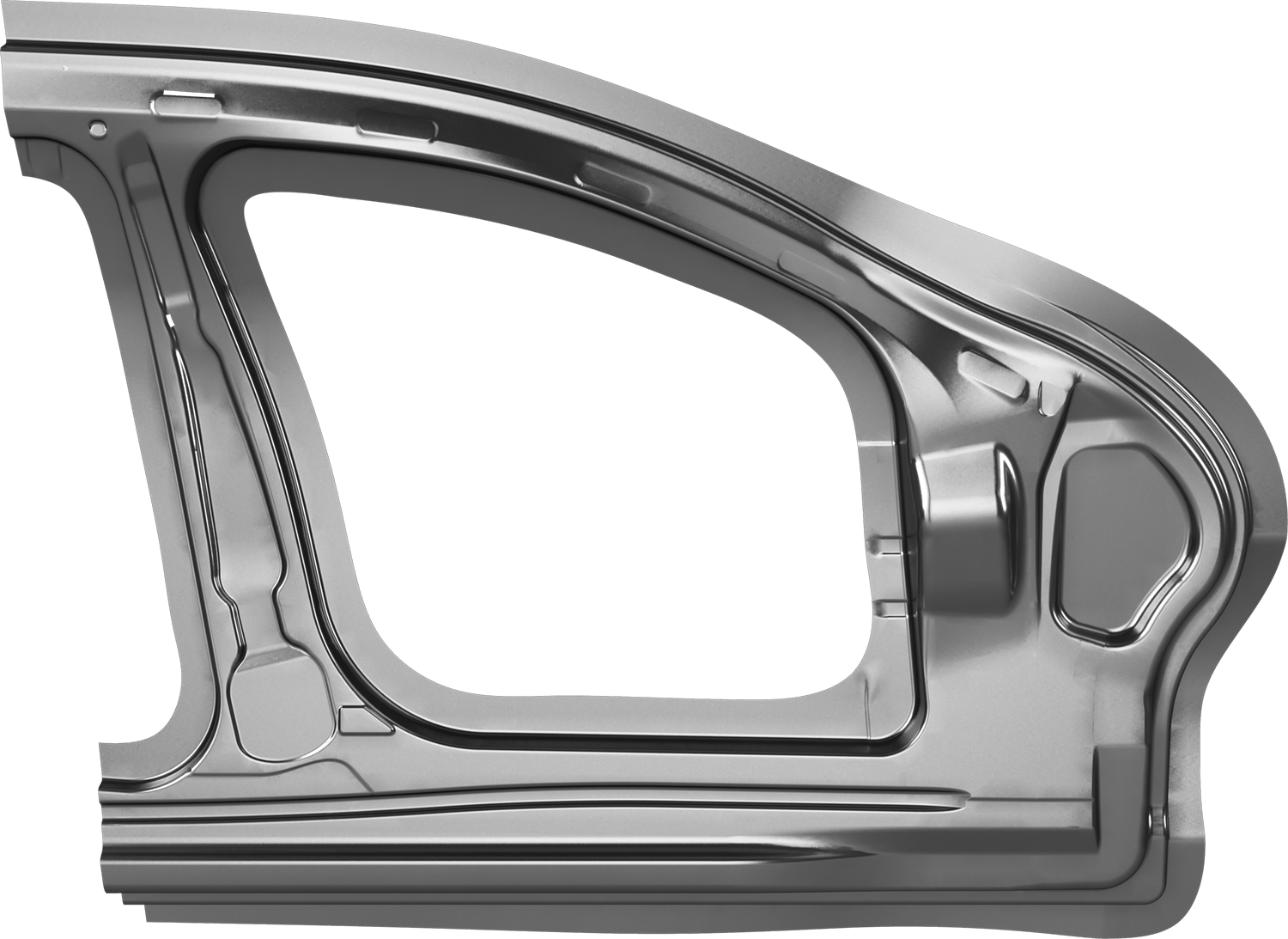

AP&T’s solution allows structural parts that have previously been manufactured from sheet steel or cold-formed aluminum to instead be produced from hot-formed high-strength aluminum. This means material thickness can be reduced and component weight can be lowered by between 30 and 50 percent, at the same time that the strength of the material and impact safety are improved.

Increased formability and more rational process

Our process technology significantly increases the material’s formability, which means that high-strength aluminum can also be used for complex-shaped parts. Additional features and qualities can be integrated into a single component. Among other things, this means that components that are currently manufactured from several joined parts can now be produced in far fewer steps.

The rational process also results in cost advantages. Fewer parts, fewer manufacturing steps and fewer required tools combined with more effective management, logistics and assembly result in a very competitive total cost of ownership.

Complete solution with a high degree of flexibility

AP&T offers complete and flexible production solutions for hot forming, w-tempering and warm forming of high-strength aluminum (6000 and 7000 series). Among other things, AP&T’s most recent press, which offers a quick, stable and energy-efficient process, is included, as are AP&T’s Multi-Layer Furnace and automation.

AP&T’s experts: “Our solution for hot forming of car body parts out of high-strength aluminum can result in weight savings of up to 40 percent”.

Read the full article here.

Recipient of the 2017 Altair Enlighten Award

AP&T’s solution for hot forming of high-strength aluminum recently won the prestigious 2017 Altair Enlighten Award competition in the Enabling Technology category. The competition recognizes important innovations that can contribute to lighter and more energy-efficient cars.