Nissan in the UK stepping up the pace with AP&T's help

By automating one of their existing press lines with AP&T's help, Nissan Sunderland Plant is planning to increase the company’s production capacity by about 900,000 large car body parts a year.

Nissan's facility in Sunderland is one of the largest car plants in Europe with annual production of around half a million cars. Manufacturing has heavily increased since the factory was built at the end of the 1980s.

As a means of keeping up with growing demand, plant management decided in 2012 to increase the capacity of the plant's own press shop to support continued growth.

The choice was either to modernize Nissan’s own process or to purchase body parts at a significantly higher cost from subcontractors. Since the presses in the tandem line were in good shape, a decision was taken to keep and equip them with new automation.

Another project with AP&T

At about the same time, Nissan Sunderland Plant were working with AP&T on another automation project called Autoloader*, which aimed to streamline the manufacture of small car body parts.

Nissan’s experience from working with AP&T made it natural to continue with the same partner on the new project, which was much more extensive.

Faster pace and quicker tool changes

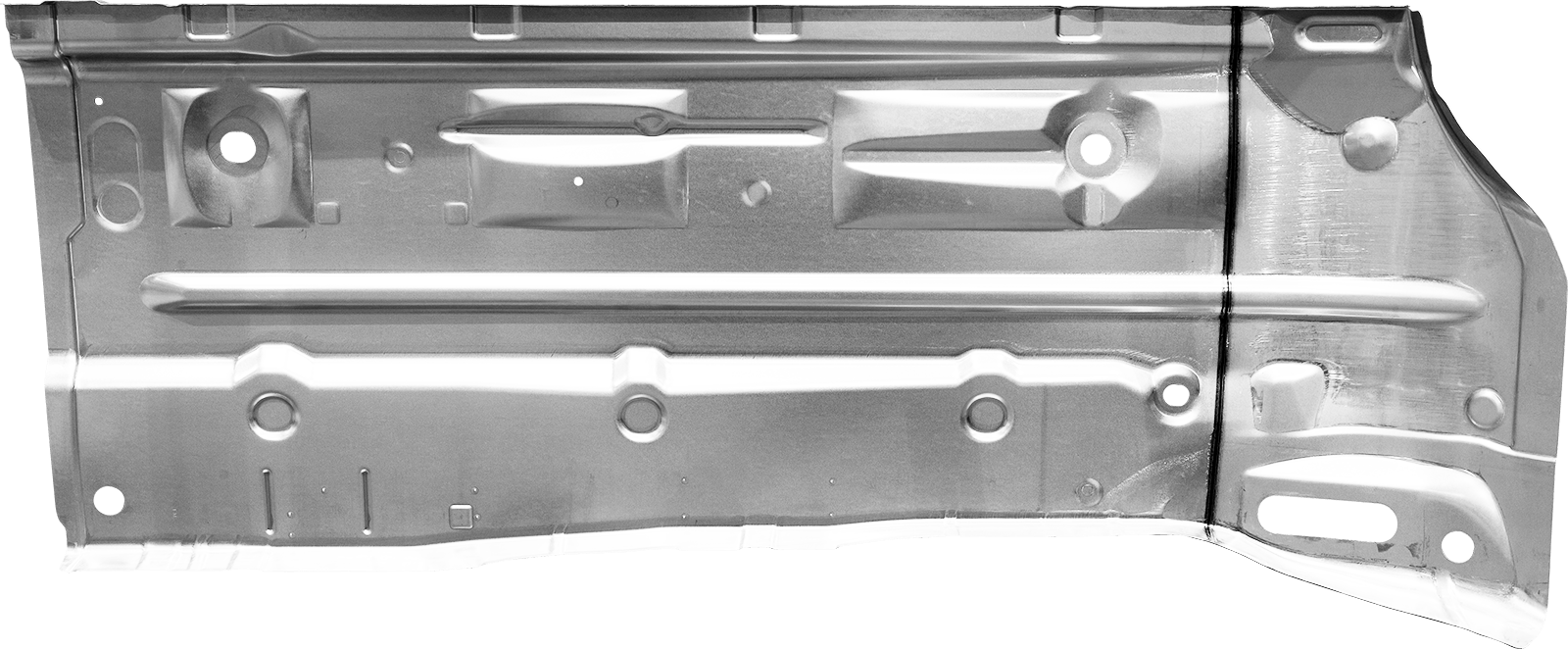

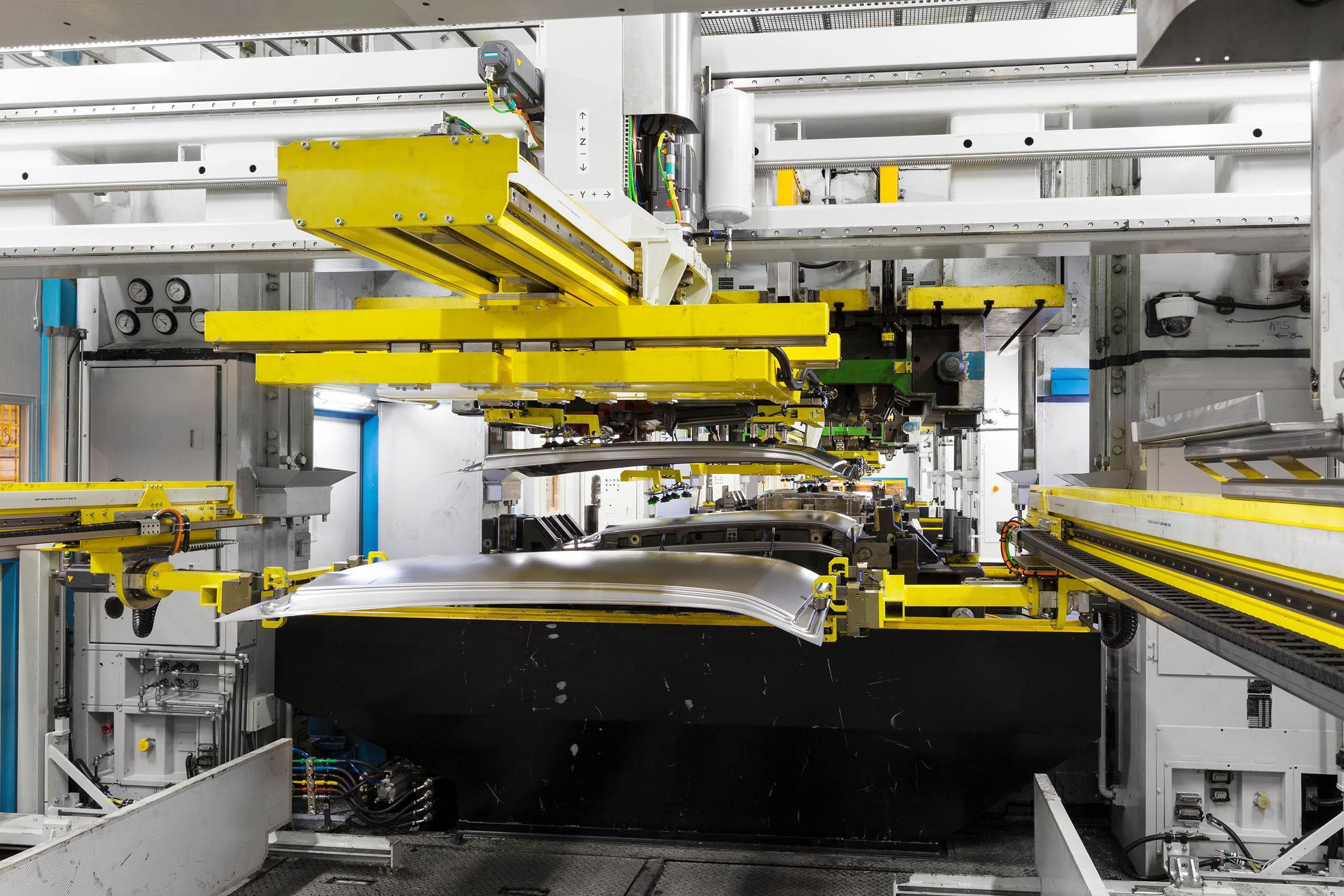

The solution was to reduce the number of original presses in the tandem line from five to four. Together with a destacker and ten SpeedFeeders, the remaining presses now constitute an integrated line with high capacity that is used to manufacture metal panels for doors, roofs, floors and trunks.

The pressing rate has increased by 45 percent compared to manual operation, and there is still potential for improvement.

Total cycle time has also been reduced thanks to a less complex tool design. The automatic system for changing tools and grippers has cut set-up times in half. This is also true of the noise level in the press shop, which has greatly improved the work environment.

The successful cooperation with Nissan has provided AP&T with a great deal of valuable experience.

"The mutual exchange of know-how allowed us to build up a relationship that opens up new possibilities for the future as well," says Martin Sahlman, Product Manager Automation Systems at AP&T.

Peter Karlsson, Managing Director at AP&T in the United Kingdom and Denmark agrees.

"Nissan is a strong brand with quick technological development, and it is great to be a part of their journey."

*AP&T's cooperation with Nissan in the United Kingdom started in 2011 in conjunction with the Autoloader project, where metal waste which had previously been scrapped was now instead used to manufacture small car body parts.

June 2014

Facts

- Large metal panels are manufactured in Nissan's automated four-press line for the Qashqai, Juke and Note car models.

- AP&T supplied a turnkey solution with a destacker, ten SpeedFeeders and an automated system for changing tools and grippers, in addition to project management, installation, start-up and training.