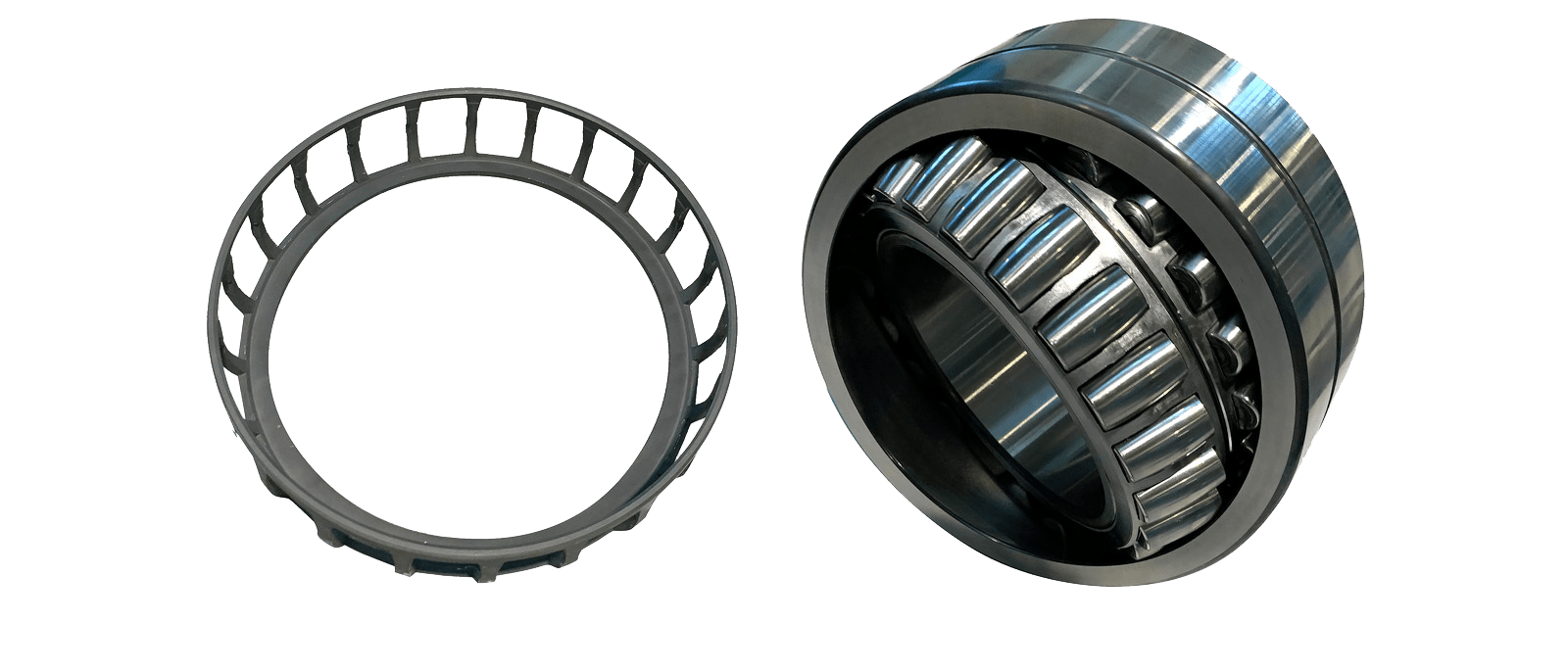

NKC Sweden is looking toward the future by investing in AP&T's press line for producing roller bearing cages

One of the main business areas of NKC Manufacturing Sweden in Gothenburg is the manufacturing of pressed, stamped and machine molded products for industrial companies. With its approximately 140 employees, the company is the European branch of the Japanese industrial group NKC (Nakanishi Metal Works), which operates around the world. Early in 2020, they invested in a new, fully automatic press line from AP&T to replace old machines and to ensure their production. But the relationship between the companies stretches back much further than that.

“The first AP&T machines were installed here in the mid 1980s when we were part of SKF. Since then, the equipment has been regularly expanded, updated and added to while service, maintenance and repairs have been made by AP&T on an ongoing basis,” says Charles Wallin, Project Manager of Process Development at NKC Manufacturing Sweden.

Investment to secure production

To increase their capacity potential and to ensure their deliveries, NKC made the decision in 2019 to upgrade one of the existing machine lines that produces roller bearing cages with new equipment from AP&T. The fully automated production process includes a number of operations such as blank feeding, drawing, cutting, washing, spinning, unloading and stacking.

“We received the order in April 2019 and had the new line installed by January the following year, as planned. We supplied a 630 ton press, two SpeedFeeders, a High Speed Destacker, grippers, protection guards and a control system. It was vital to integrate our equipment with the existing punching press, lathe and other machinery used in the complete line so they would continue to have an uninterrupted, efficient flow,” says Kristian Broberg, sales manager of the deal on the AP&T side.

Smooth collaboration

The installation was done on time and the equipment has since then been in operation. To ensure high reliability in the long-term, NKC chose to enter a service and maintenance agreement with AP&T. Charles Wallin is satisfied.

“Our collaboration with AP&T, not least with their project managers, has been very smooth. They are easy to work with, and not only to they understand our needs, but they can meet them efficiently. The fact that they can supply complete solutions and take responsibility from start to finish is an enormous advantage, as is their geographical location. The new line has brought about substantial improvements in every way and is an important investment in the future,” he says.

December 2020