AP&T and ESI first out with virtual process modeling for high-strength hot-formed aluminum

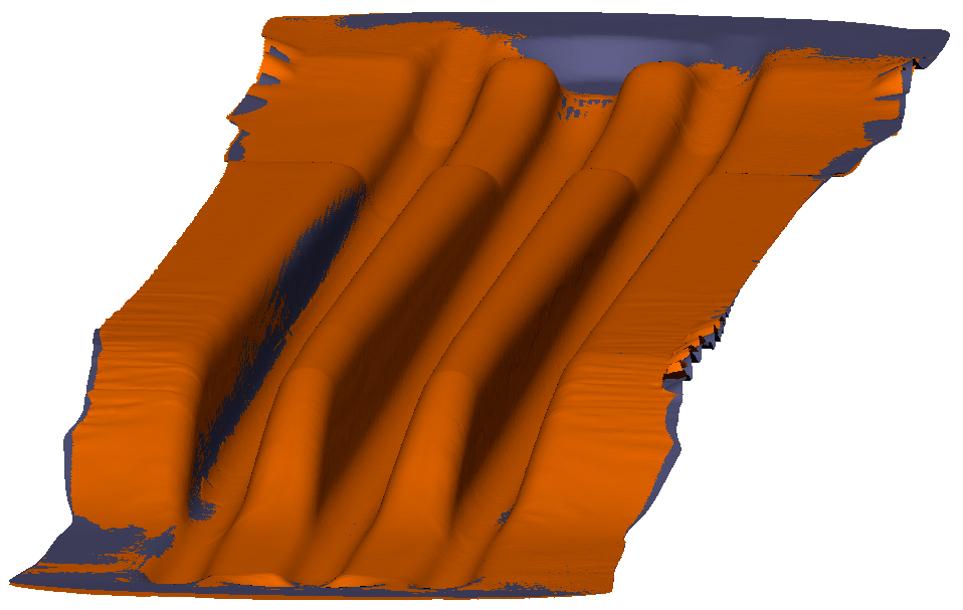

Using advanced simulation tools, AP&T and ESI have implemented several virtual models that reflect the process for hot forming of high-strength aluminum (AA6xxx and AA7xxx).

The simulations have been compared to the results of real tests performed at AP&T’s R&D facilities in Ulricehamn, Sweden, and the outcome shows a very high degree of conformity. Consequently in the near future, AP&T is planning on being able to offer its customers in the car industry a unique opportunity to virtually test parts and complex-shaped components made of high-strength hot-formed aluminum, so that they can lower their development costs and shorten lead times.

“As One Responsible Partner not only in the field of press hardening of steel, but also in the field of high strength aluminum forming technologies, we constantly develop our capabilities to make our customers more competitive on a global market,” says Dr. Christian Koroschetz.

The results of these studies will be presented at several events during the course of 2017, such as the Automotive Engineering Congress in Nürnberg and the CHS2 Conference 2017 in Atlanta.