Press Hardening

Watch our video “The Future of Press Hardening” where AP&T CTO and Head of R&D Dr. Christian Koroschetz highlights the latest developments within press hardening and offers a glimpse into future solutions.

AP&T leading development

AP&T is one of the world’s leading suppliers of complete, turnkey production solutions for manufacturing press hardened vehicle parts and one of the true pioneers in the industry. Since 2001, we have installed over 140 press hardening lines for customers globally, which has given us unique experience.

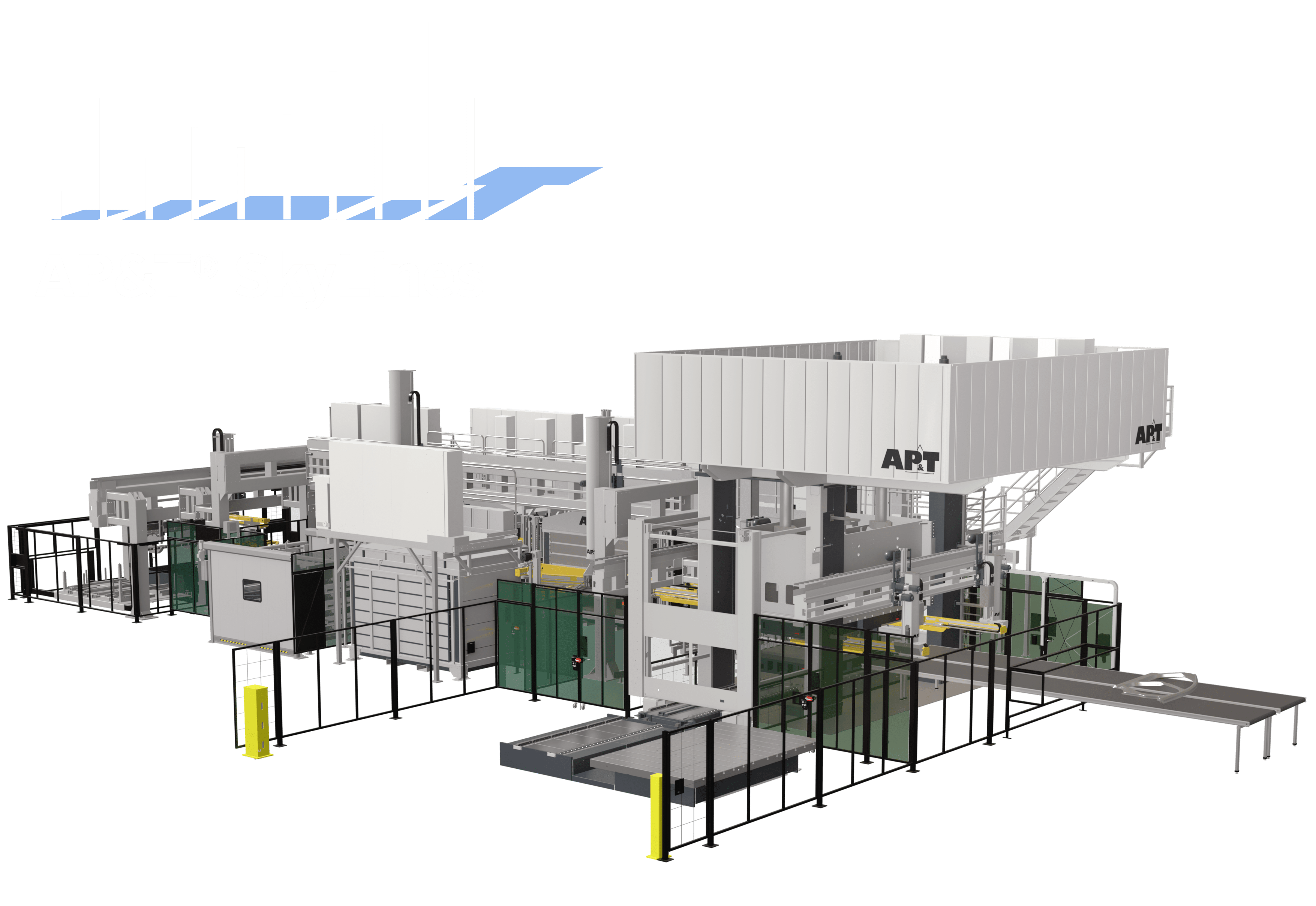

AP&T® SkyLines——大型复杂集成部件的高效热成形解决方案

AP&T® SkyLines 代表了下一代先进的热成形技术。专为大型复杂板料和高回收率材料设计,AP&T® SkyLines 能够实现轻量化集成部件的高效生产,在最大化材料利用率的同时,显著降低环境影响。

Partner with complete responsibility

As a partner of both OEMs and subcontractors, we take complete responsibility. Not only can we supply the needed equipment, we can also provide training and support during the start-up phase of new product manufacturing. We gather all of our core expertise at AP&T to ensure that we can offer our customers easy transactions with few contact interfaces and a long-term secure, cost efficient and productive solution. One single project group will take care of the entire process from needs analysis to installation and start-up. Preventative maintenance, production optimization, training and performance analyses are conducted by AP&T's aftermarket organization, whose technicians are specially trained in press hardening technology.

New methods and materials

As a result of our own R&D department and established partnerships with academia and industrial partners, we continue to lead development within press hardening, as well as pave the way for efficient forming methods for aluminum and other lightweight materials. Amongst other things, our Tech Center in Ulricehamn has a full-scale press hardening line for demonstration, technology development and pre-production.

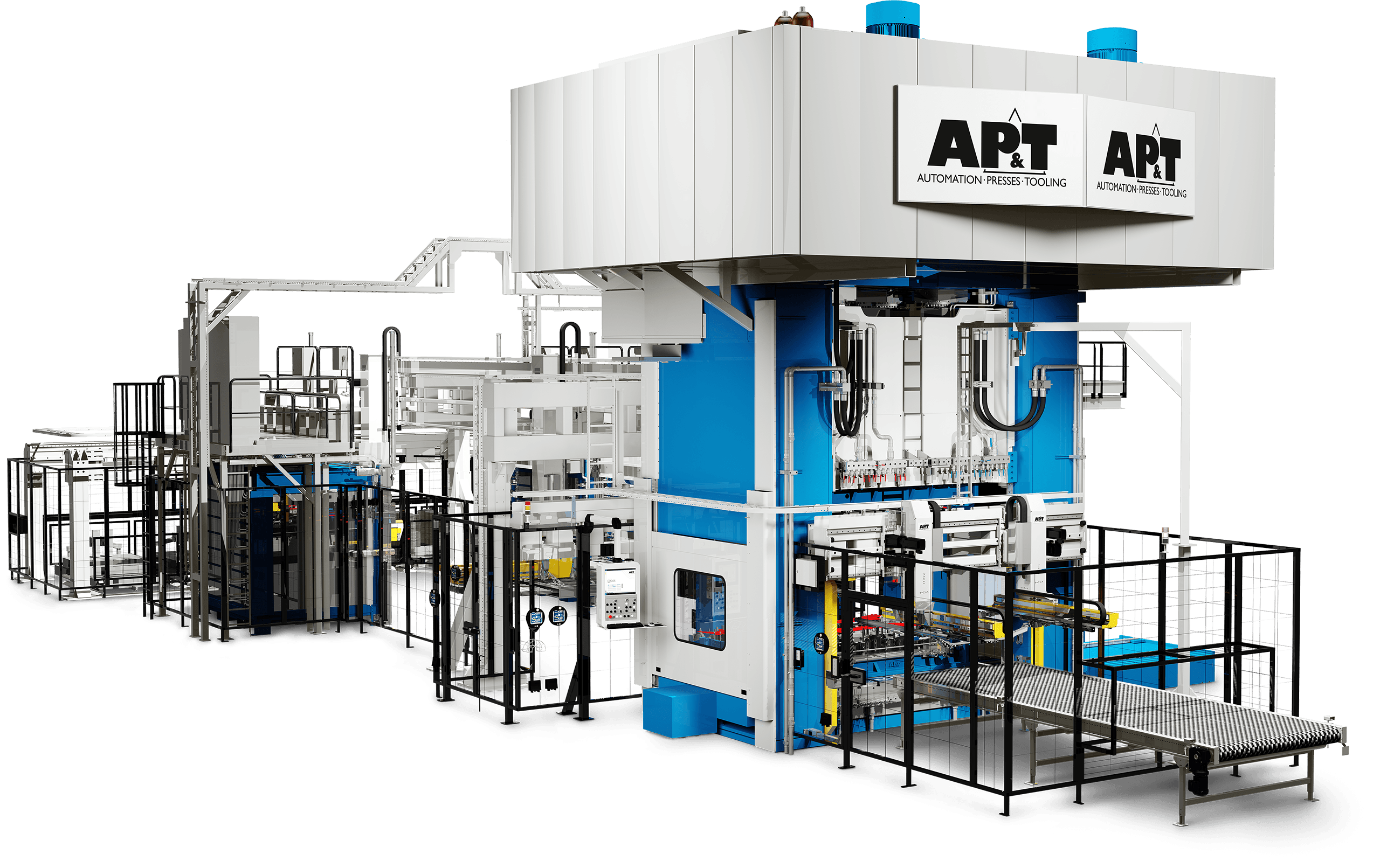

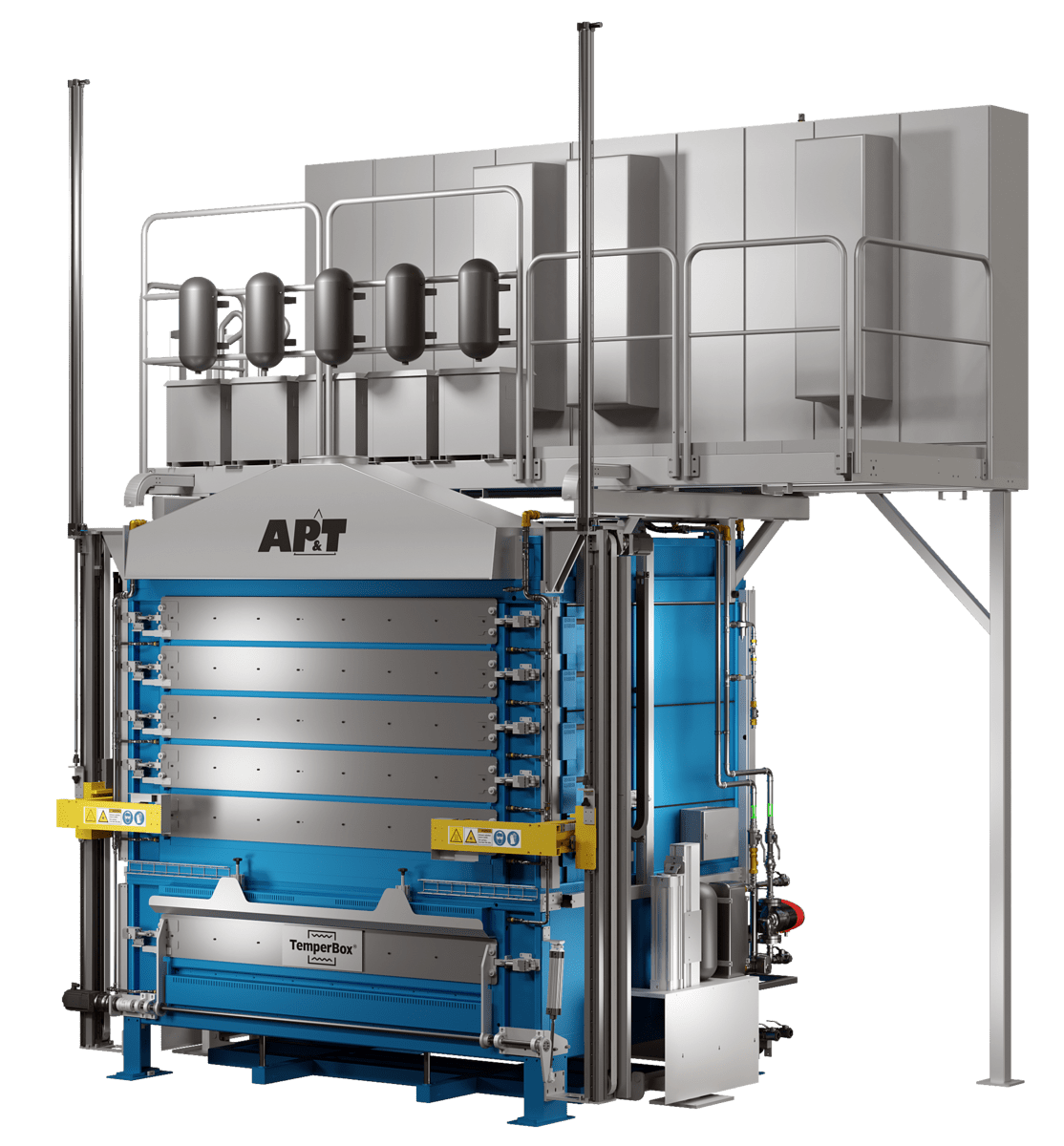

Complete and compact

AP&T's production solutions for manufacturing press hardened parts include all of the required technical equipment such as presses, automation, tooling and furnace systems. The solutions are based on AP&T’s well-tested system of standard modules, which provides a great deal of flexibility, high degree of reliability and compact, space-efficient design.

For example, our own Multi-Layer Furnace (MLF) has several advantages compared to conventional roller hearth furnaces. The concept allows several furnace modules to be stacked on top of each other, which means the installation is extremely space-efficient. Production can also be scaled up or down based on need, and heating can be adjusted thereafter. Since the furnace only contains a few movable parts and the blanks are immobile during the entire heating process, the risk of both downtime and damage to materials is reduced.

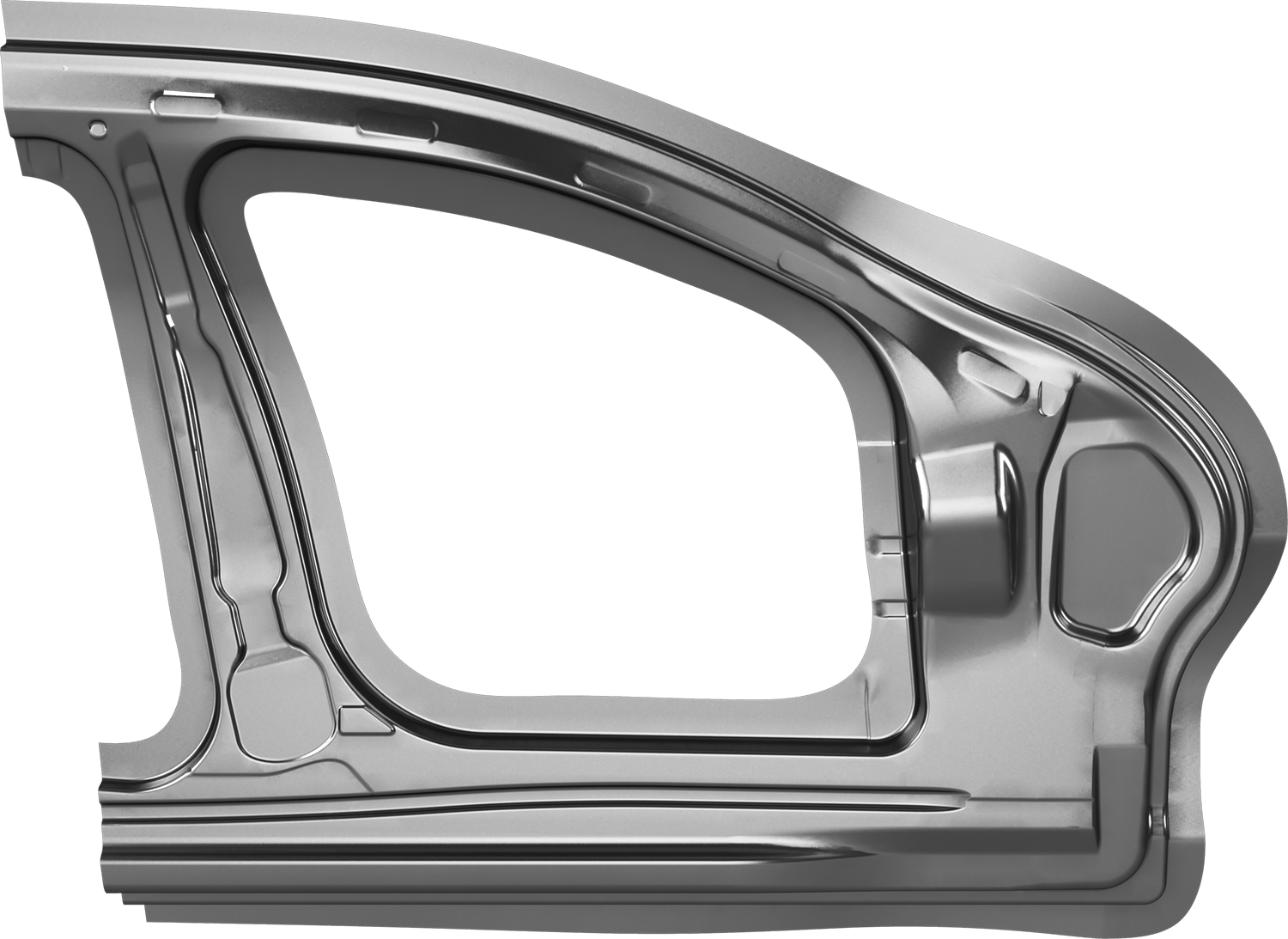

TemperBox® – tailored properties in press-hardened components

AP&T’s patented solution for partial press hardening of structural parts – TemperBox® – allows hard and soft zones to be combined in a single finished part, paving the way for innovative body designs and cost-efficient production. Individually defined areas of press hardened components can be fully hardened to maximize strength while other areas remain soft in order to achieve the desired ductility and to facilitate post processing such as joining or mechanical cutting. This means designers and manufacturing engineers can work more freely without considering costly reinforcements or cycle time intensive hardening processes. TemperBox® can be integrated with AP&T's new and existing Multi-Layer Furnaces, as well as be combined with any other type of heat treatment equipment.

更轻量 · 更安全 · 更节能

搭载 AP&T独特的 TemperBox® 技术热成形生产线,助力制造商实现具有定制材料性能的车身部件——通过结合硬区和软区,以提高碰撞安全性、减轻部件重量并实现高效生产。同时,AP&T® 伺服压力机和多层加热炉可分别降低能耗高达 70% 和 40%。

观看视频,了解我们如何推动汽车制造技术革新。

In-line process monitoring for higher product quality

AP&T's in-line process monitoring system enables an optimized and well-controlled press hardening process, which ensures the formed part has a high and consistent level of quality. In addition, cycle times can be reduced.

Pyrometers and infrared cameras are used to measure the material’s temperature with a high degree of precision both before and after pressing. The pyrometer registers the absolute temperature at a certain point, while the infrared cameras are used to read the heat distribution on the part’s surface. All of this takes place without any of the equipment coming into physical contact with the material.

In-line process monitoring fulfills automotive industry standards, such as CQI-9.

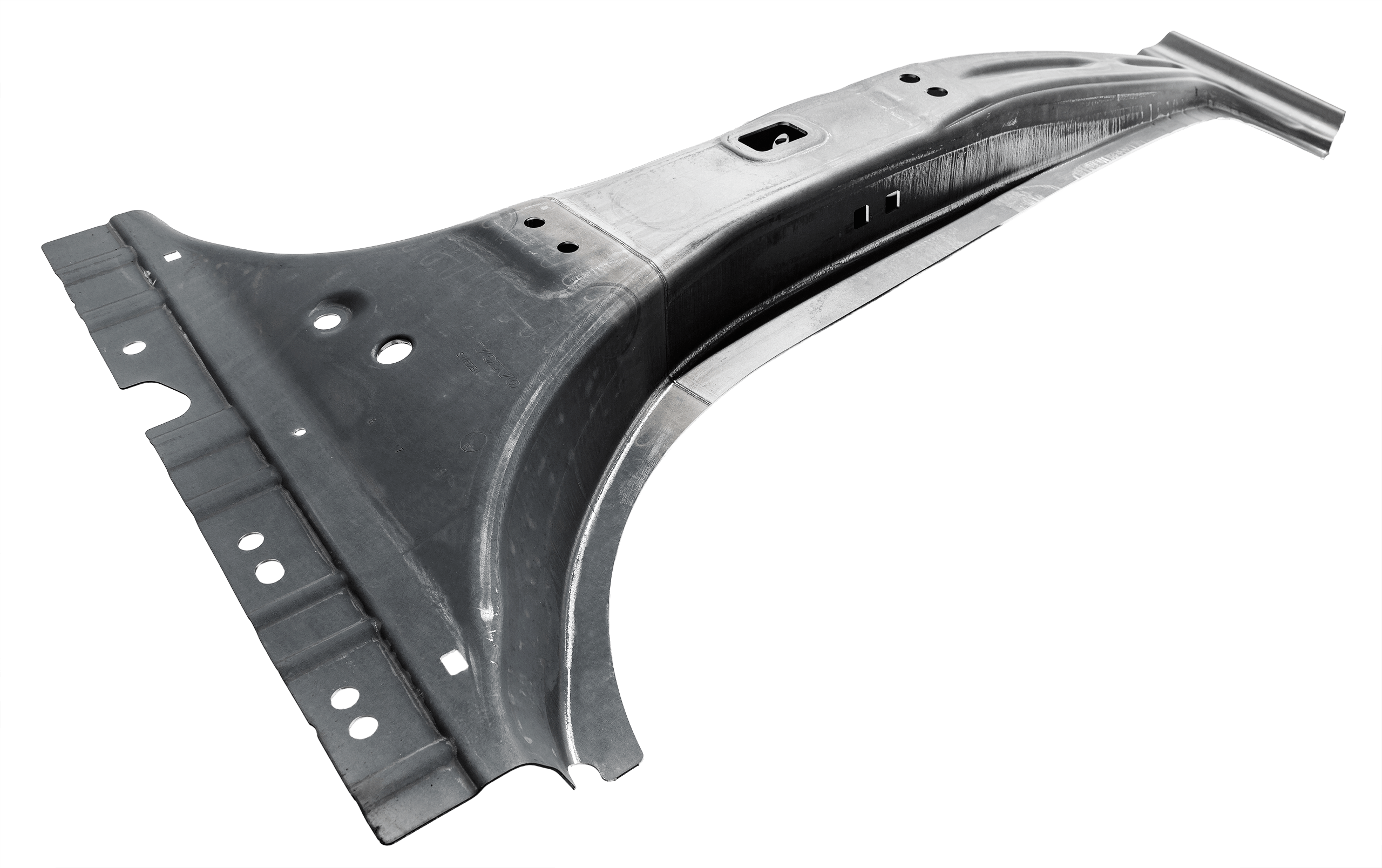

Strong, light and dimensionally stable – advantages of press hardening

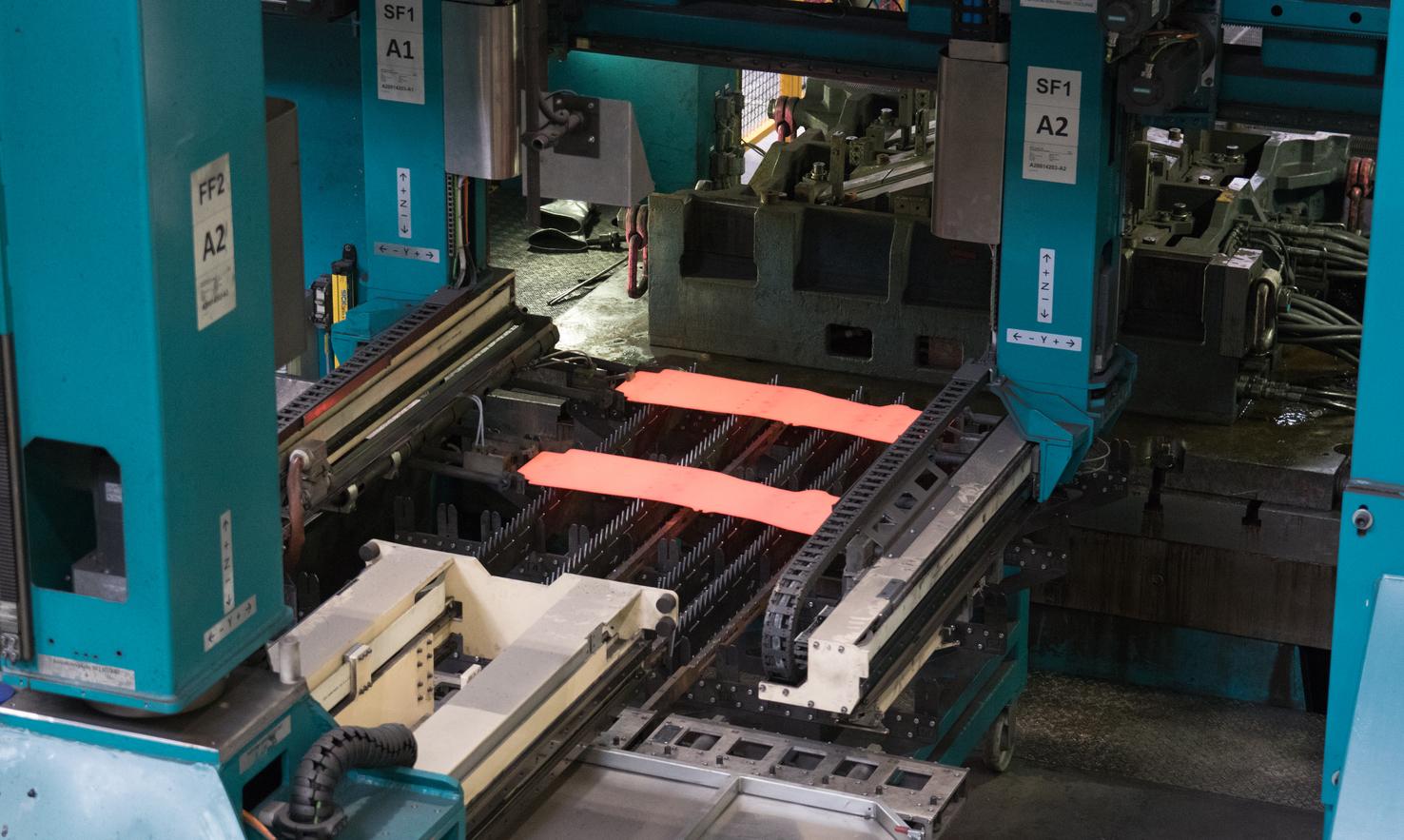

During press hardening, boron steel blanks that can be hardened are heated up to a high temperature (930 degrees), formed and cooled in a carefully controlled process. During the process, the steel’s molecular structure is transformed into ultra high strength steel (UHSS). The finished part is three times more stable than the original material, and it becomes extremely strong in relation to its weight.

The method also enables manufacture of complex-shaped parts with high dimensional stability and a great deal of repeat accuracy in a quick and cost-efficient manner. This means that press hardening technology is extremely interesting to the automotive industry, where increasingly tougher demands for higher levels of safety and improved environmental properties are strong driving forces for continued development.

Using a larger proportion of press hardened body parts means that collision safety can be enhanced at the same time that the car becomes lighter, which helps lower fuel consumption and carbon dioxide emissions. A weight savings of 100 kg means that fuel consumption can be reduced by an average of 0.5 liters for every 100 km driven. Due to the advantages offered by press hardening technology, most car manufacturers have substantially increased their usage of press hardened parts. Up to 20–40 percent of the weight (body in white) of some car models consists of press hardened materials.