Mekoprint in Denmark increases production capacity with new press line from AP&T

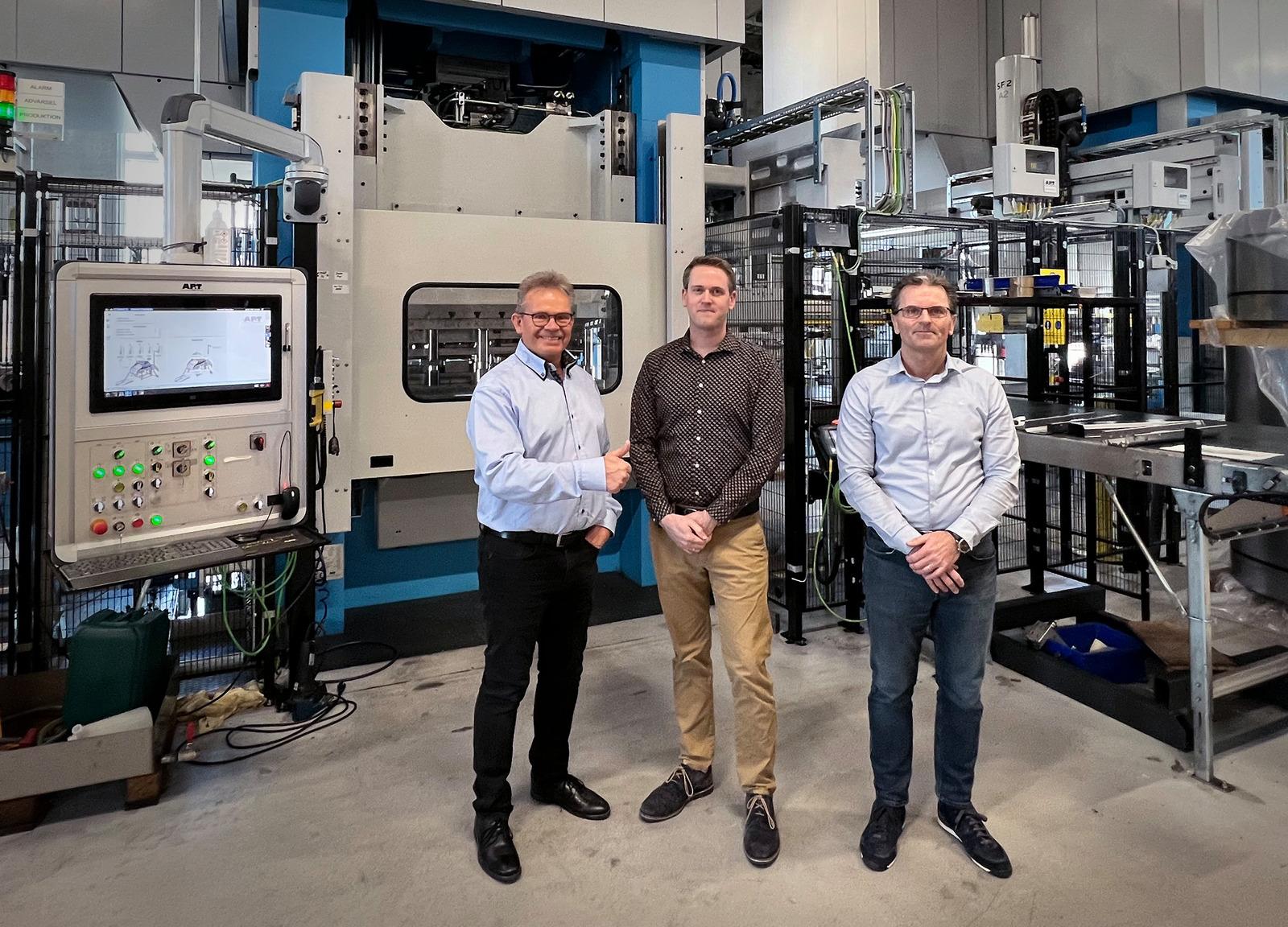

Mekoprint Mechanics in Aalborg, Denmark has ordered a new press line from AP&T for delivery and installation in 2022. The new line, the company’s third from AP&T, will not only increase production capacity, but will also enable manufacturing of large metal components and parts.

“Following a period of great fluctuation in demand for our products, we are now seeing a strong recovery from many of our customers. To increase our capacity and strengthen our competitiveness, we are making a substantial investment in new buildings and machines, of which, the new AP&T production line is an important part,” says Karsten J. Møller, Technology & Product Manager at Mekoprint Mechanics.

Mekoprint Mechanics manufactures cabinets, chassis parts, front panels and other metal parts and components for a large number of companies in different industries on the global market. They are now expanding their facilities in Aalborg by about 2,500 m2 to 19,000 m2 while investing in a new, versatile production line from AP&T for forming sheet metal components. To be installed in the autumn of 2022, the new line includes a press with 500 tons of press force, a 1900 x 1600 mm press table, and a SpeedFeeder for unloading. The order also includes two years of complete service and maintenance.

Just over three years ago, they installed a similar line, which saw the addition of another press in 2019. But AP&T has an even earlier history of delivering equipment to Mekoprint.

“We have been collaborating with AP&T for decades and we are thoroughly confident in their ability to deliver technology that meets our needs for reliability, flexibility and productivity. Having access to quick, local service is also highly beneficial to us,” says Møller.

“It is great that Mekoprint is now strongly investing in the future and that we at AP&T are part of their expansion journey,” says Peter Karlsson, Key Account and Area Sales Manager at AP&T.

The new production line in brief

- Comprised of a hydraulic press with 500 tons of press force (main cylinder 500 t, cushion cylinder 250 t, third cylinder at 50 t), a 1900 x 1600 mm press table and SpeedFeeder for unloading.

- For forming/punching components from coils or blanks.

- Two years of service and maintenance included.

Mekoprint Mechanics in brief

- Manufactures cabinets, chassis parts and front panels in various materials and into a number of end products for customers in many industries.

- Extensive machine park with various sheet metal processing technologies.

- Production facility of about 19,000 m2 in Aalborg, Denmark.

- Part of the Mekoprint Group, established in 1954.