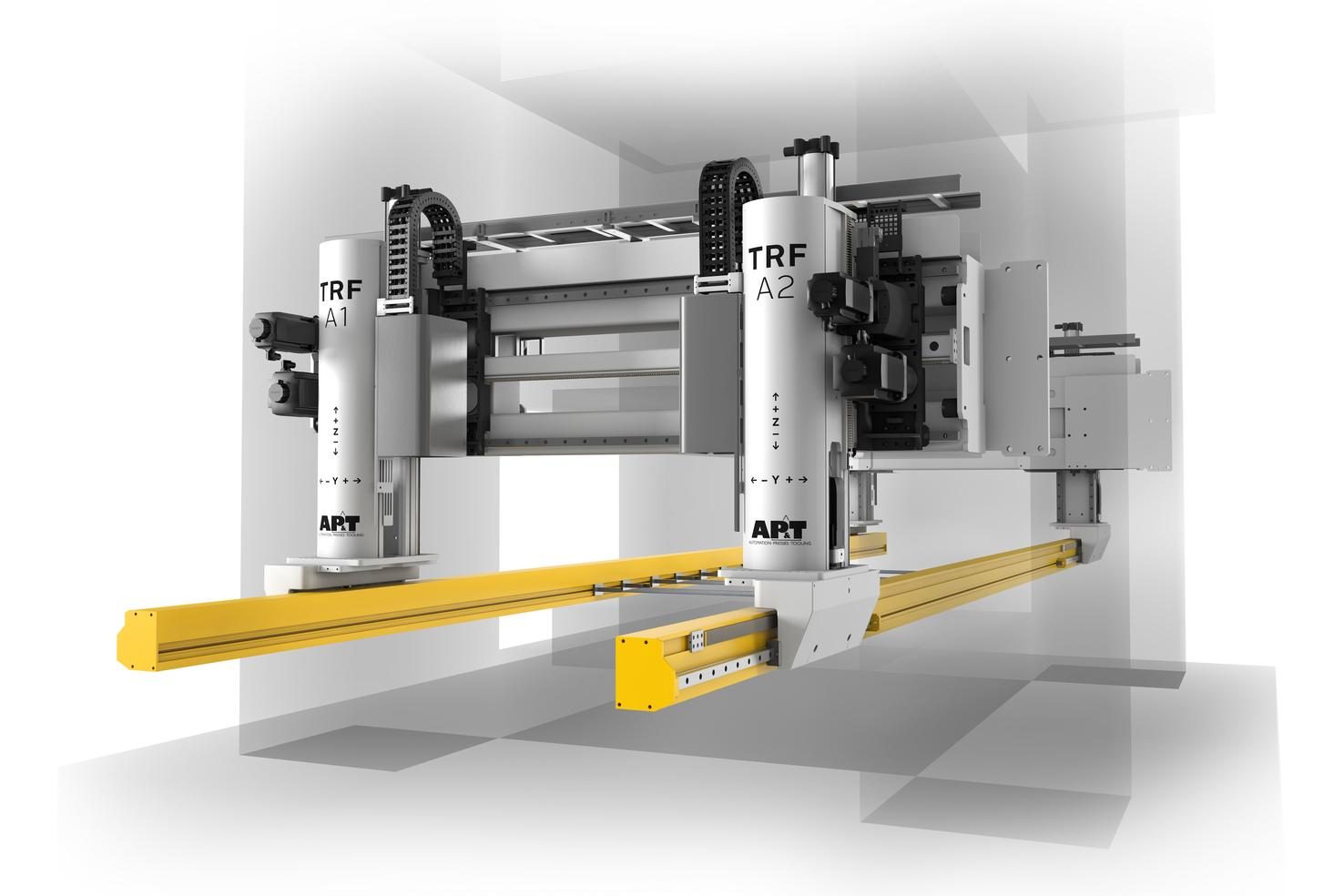

AP&T is strengthening its position as one of the leading manufacturers of linear automation. The company is launching an entirely new generation of fast and energy-efficient press robots, transfer systems and other automation equipment – an initiative that is paving the way for increased efficiency and productivity for AP&T’s customers.

“With our new and future-proofed products, we can meet our customers’ needs today and in the future, at the same time that we are taking a step into Industry 4.0,” says AP&T Product Manager Martin Sahlman.

Acceleration in the new generation of automation products is approximately 20 percent faster than previously, which enables significantly shorter cycle times and higher production capacity. Since the structural parts are made of lightweight materials, weight and energy consumption are also greatly reduced. A new SpeedFeeder is approximately 10 percent more energy efficient than the previous model. Compared to conventional industrial robots, the difference can be as much as 50 percent.

The products are manufactured with AP&T’s standard modules, which in and of itself is a key to a high degree of reliability. In order to improve reliability and availability additionally, the designers have reduced the number of included components and parts, at the same time that several functions that were previously options are now included in the standard version.

The equipment has also been prepared for connection to smartphones and tablets, for example, in order to simplify reading of machine status and production statistics via the Internet.

The new generation of automation equipment from AP&T will be presented at EuroBLECH in Hannover between October 25 and 29.