As we all know, we are in the midst of the Fourth Industrial Revolution, Industry 4.0, where connected, fully automated machines that communicate with each other enable smarter and more efficient production. AP&T, a leader in modular-based linear robots, sees a great deal of potential in the changes currently taking place in the manufacturing industry.

“The technology is developing quickly, and opportunities for new applications that can improve our customers’ competitiveness in the global market are growing as well,” says AP&T Product Manager Automation Martin Sahlman.

One example is AP&T’s latest program of intelligent, connected automation solutions. The new technology has laid the groundwork for increased production speed, more consistent and efficient flows, greater reliability and lower energy consumption. The end result for the customer is higher productivity.

“Since customers now have access to a large amount of relevant machine and production data, the process can be optimized and integrated in an entirely different way than previously. Planning service and maintenance will be easier, as will preventing stoppages and implementing continuous improvements.”

The Fourth Industrial Revolution is certainly unique in terms of content, opportunities and development rate, but it is also a continuation of the previous three revolutions. Rationalizing and automating processes is nothing new in and of itself.

“Constantly aiming to do things better and more efficiently is in the nature of industrial development. Automation in the modern sense gathered speed after the Second World War and has continued to accelerate since then. By staying at the forefront of development, we can continue producing the solutions that our customers need to address the future. And it is not only a matter of maximizing production capacity; rather, it is also a matter of streamlining utilization of energy and materials while at the same time creating a better and safer work environment,” says Martin Sahlman.

Facts

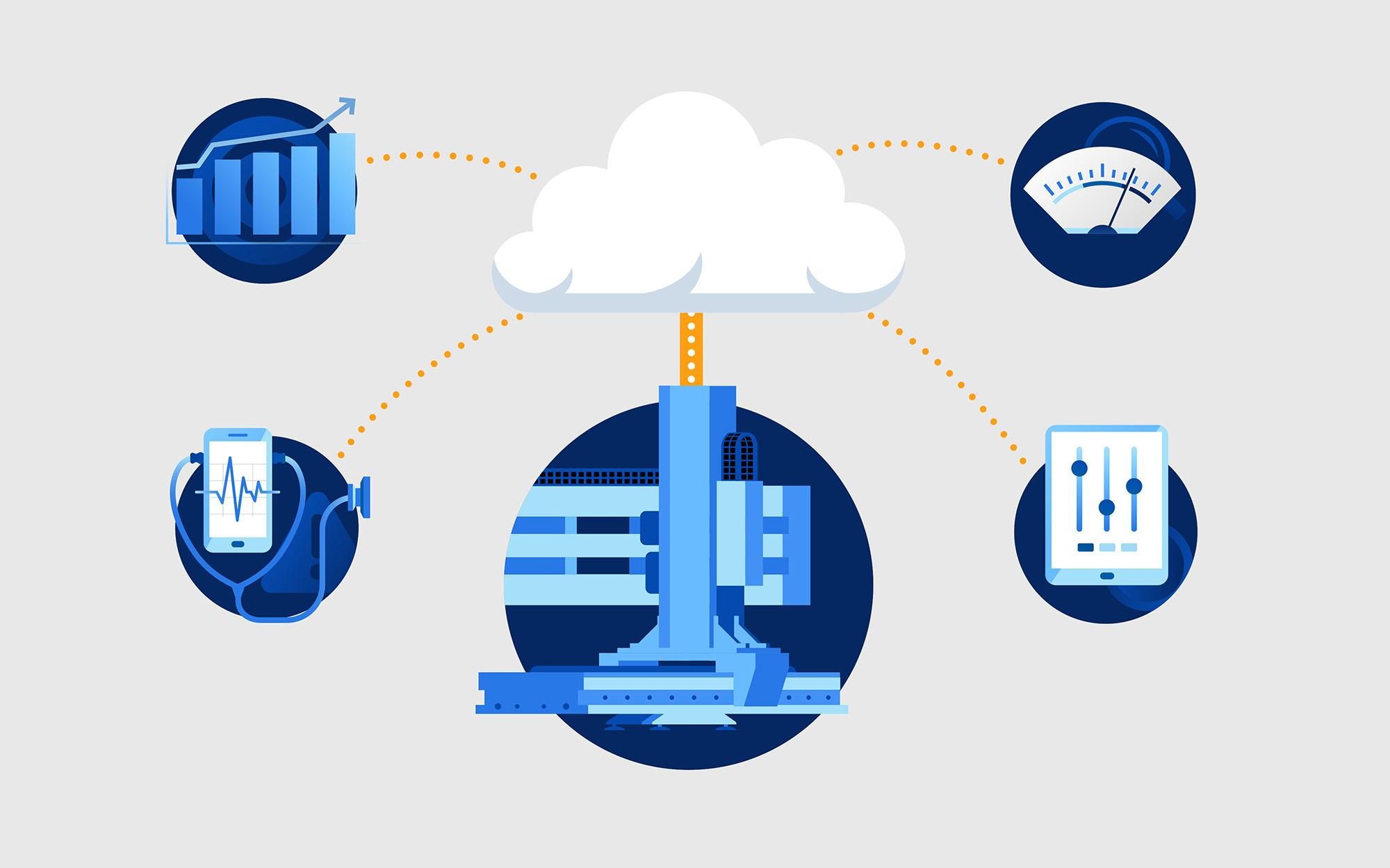

AP&T’s offering comprises several smart features and services which enable better control over machines and processes via a smartphone, tablet, computer or control panel. For example:

- Performance monitoring. Shows production performance, availability and OEE.

- Condition monitoring. Shows the machine’s status and service requirements.

- Process monitoring. Shows data that is critical for the process such as temperatures, flows, etc. to ensure quality in the final product.

- Energy monitoring. Shows energy consumption.

- Remote maintenance. Maintenance provided remotely.

- Usage monitoring. Monitors how the machine/line is used to improve user-friendliness.

Read more about AP&T’s automation solutions here.