Press hardening from AP&T: new system for process monitoring results in higher product quality

Higher and more consistent quality of the formed vehicle part, possibility for shorter cycle times and better control over the entire manufacturing process. This is what customers can expect from AP&T’s new process monitoring system for press hardening – in-line process monitoring – which is now being introduced to the market.

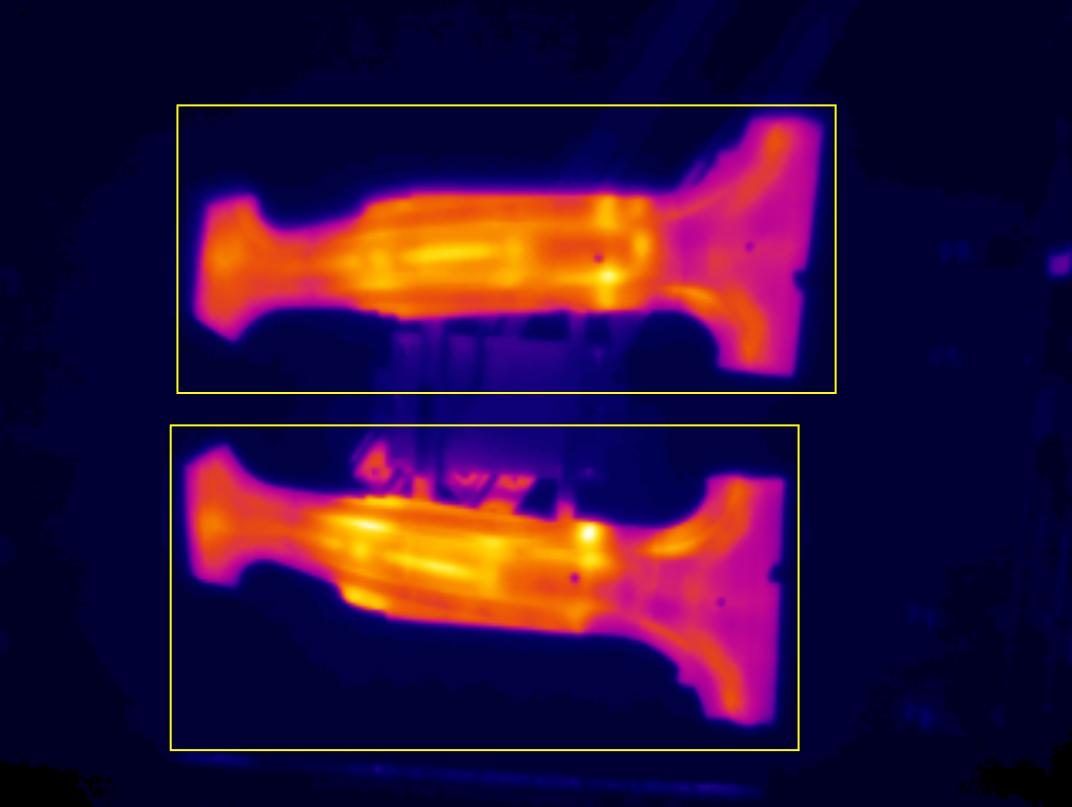

Pyrometers and infrared cameras are used to measure the material’s temperature with a high degree of precision both before and after pressing. The pyrometer registers the absolute temperature at a certain point, while the infrared cameras are used to read the heat distribution on the part’s surface. All of this takes place without any of the equipment coming into physical contact with the material. It is crucial that the blank is heated up, formed and cooled down at exactly the right temperatures to ensure that the finished vehicle part obtains the desired material properties. The higher the degree of precision, the better and more consistent the result.

“Our monitoring equipment enables our customers to achieve an optimized and well-controlled process that gives the end product a higher level of quality,” says AP&T Project Leader, Technology Development Jörgen Theander.

In-line process monitoring was developed from the start to meet the demands placed both by the process and customers, and it satisfies the car manufacturers’ standards, such as CQI-9.

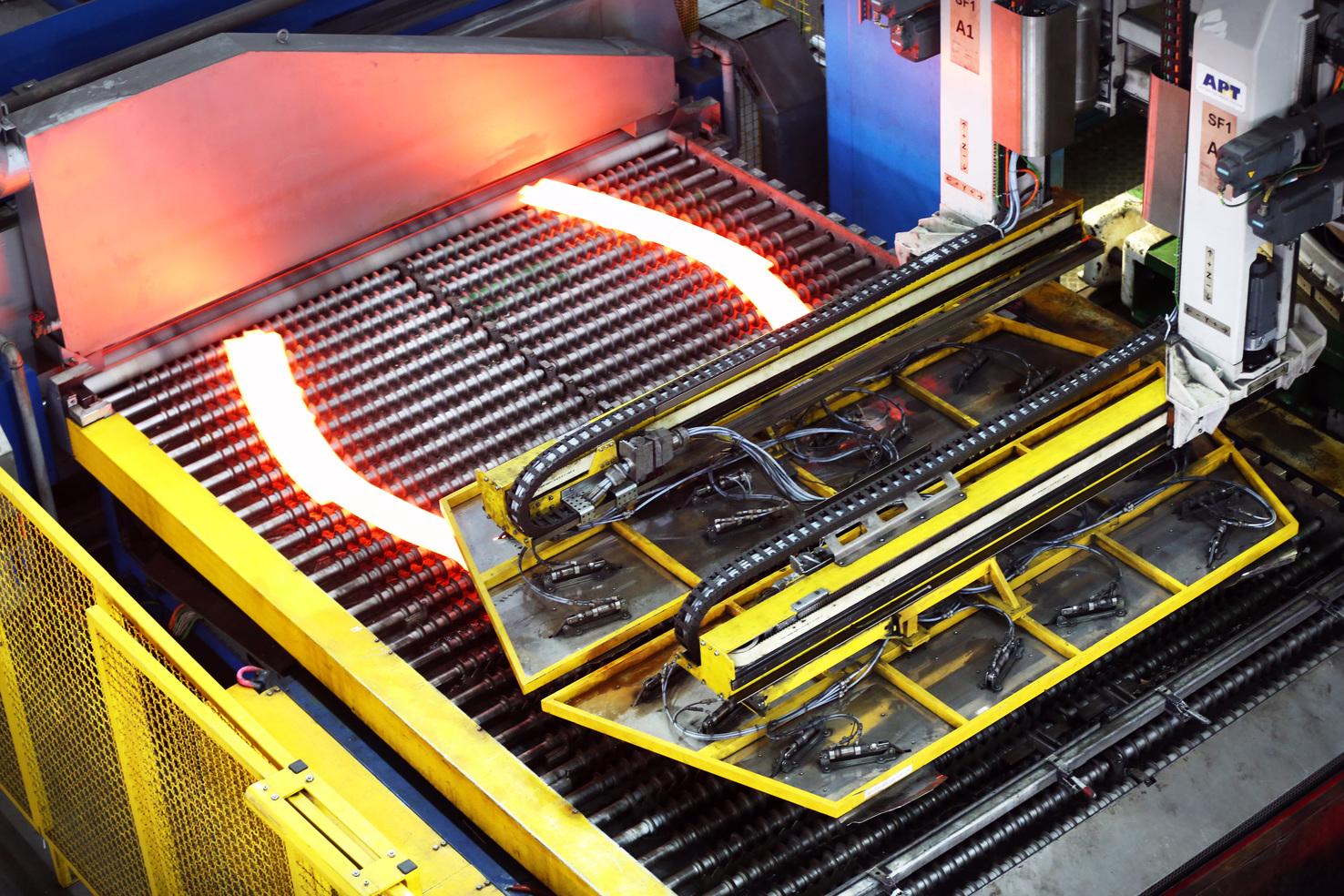

“The system was produced in cooperation with our customers, and it is designed completely in line with our specifications. It has been tested during practical operation both externally and in our own press hardening line in Ulricehamn over a one-year period. The results have been excellent, and several of our customers have already decided to invest in the new system.

The press hardening technology enables sheet metal parts to be manufactured with low weight and high strength, which results in lighter, safer and more energy-efficient cars. AP&T is one of the world’s leading suppliers of complete production solutions for press hardening. The company has installed close to 100 press hardening lines globally since the beginning of the 2000s.