Automotive

Technology for cars of the future

The automotive industry is AP&T’s largest customer segment. Customers from all over the world use our production solutions for manufacturing press hardened vehicle parts.

In addition to developing and refining our technology for press hardening of sheet steel, we invest significant resources in the development of production solutions for other lightweight materials such as aluminum and composites.

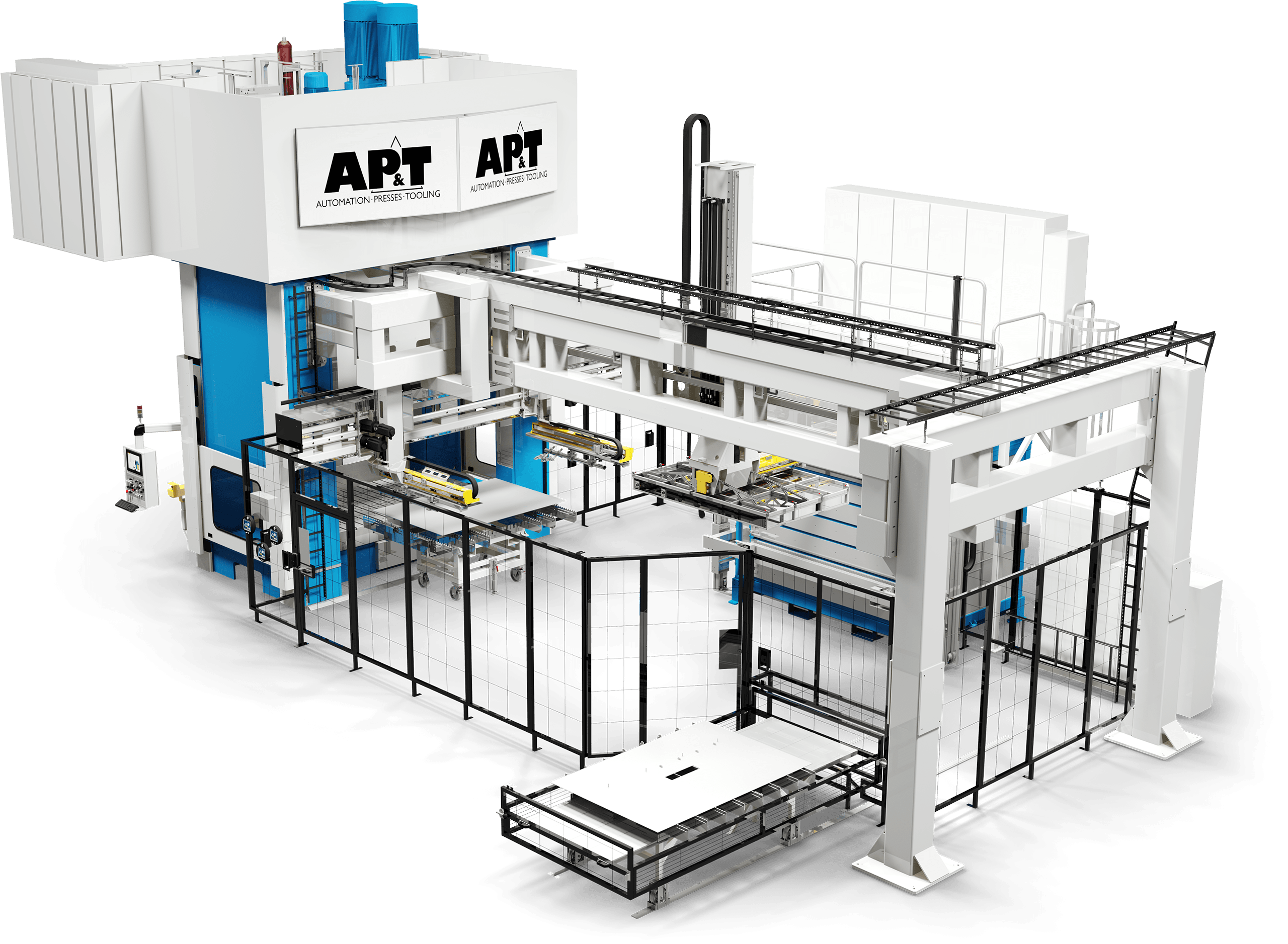

AP&T® SkyLines ——大型结构件高效能热成形产线

AP&T® SkyLines 是一条先进的热成形生产线,专为满足汽车行业对高效、精确和可持续生产的需求而打造。该生产线针对大型复杂板料和多部件集成 (MPI™) 进行了优化,AP&T® SkyLines通过精简模具数量、优化工艺流程和提升材料利用率,实现轻量化集成部件的高效生产。

在确保稳定高效运行的同时,AP&T® SkyLines 显著降低能耗与碳足迹。其灵活可靠的设计能够轻松适应不断发展的生产需求,助力制造商在快速变化的行业中保持竞争力。

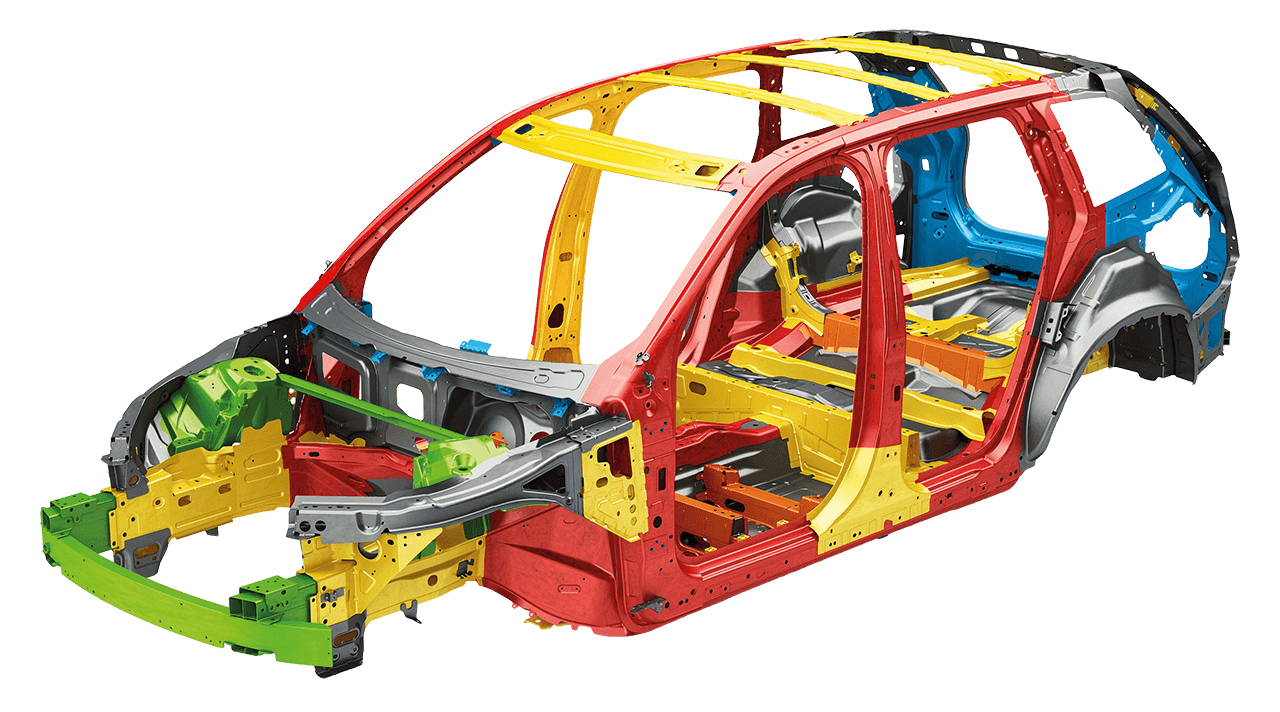

Life cycle analyses show the climate performance of processes and products

How significant a climate impact does a press-hardening line have during its lifetime? And how does the material content of structural parts affect a car's climate performance? By applying comprehensive life cycle analyses, we can provide information that makes it easier for vehicle manufacturers to account for the total climate impact of their products. They also receive detailed, third-party reviewed facts to provide guidance in making material selection and design decisions. We currently offer life cycle analyses for press hardening and hot forming of high-strength aluminum.

Automation improves productivity in existing lines

At the same time, many manufacturers have a great deal of potential in terms of rationalizing and streamlining their production of conventional cold-pressed parts. Here AP&T offers both new production equipment and automation of existing machinery and production lines – regardless of the make. For example, AP&T has automated a large number of tandem lines, which results in shorter cycle times, higher availability and improved product quality.